Are you thinking of creating a custom-made bicycle component or prototype? ColibrisODM can take care of your individual needs.

Since bike and bike parts’ shortages continue to afflict the cycling industry, on-demand manufacturing is a perfect solution allowing customers and companies to prototype custom-made products and deliver them on time — be it one unit or a thousand.

What is more, it guarantees a greater design freedom and operational agility, plus a list of other advantages that emerge when the end-use capabilities permitted by Additive Manufacturing reflect in the final product.

Here is one of the examples of how ColibrisODM was able to accommodate the need for a one-off component – a carrier: from a sketch to the final product.

The process of product development represented a series of steps that were followed.

The first stage included designing a CAD model which allowed implementing the full cycle of development for the product according to its technical requirements.

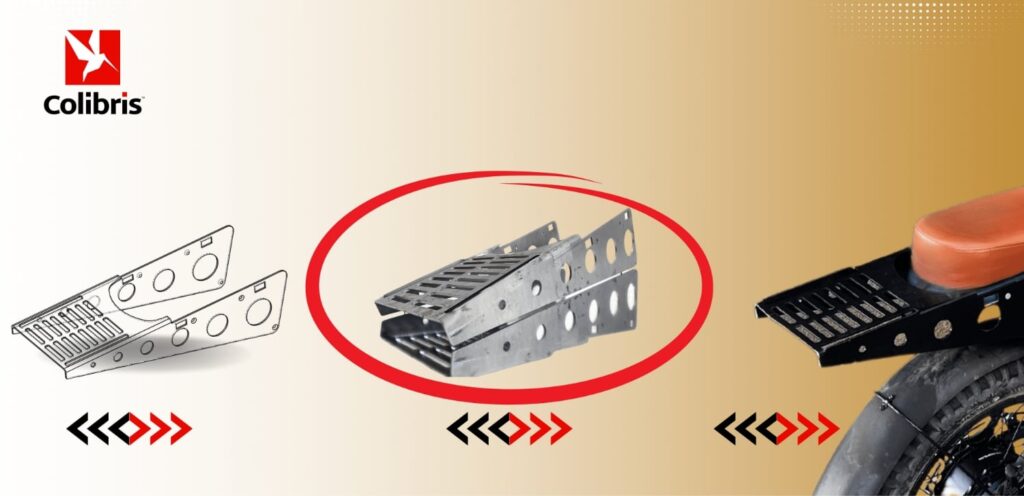

Fig. 1 An initial drawing of the carrier

Then the 3D file was uploaded to the ColibrisODM AI-driven Quoting Engine and the system selected the best production process based on the part’s geometry. ⤵️

Fig. 2 Manufactured part: custom-made carrier

“By ordering a carrier through the ColibrisODM system I was able to reduce my expenses – the part was produced in a single run and took less than a week to be delivered”, – says J.B.

This example illustrates how our client was able to scale his component to fit the demanded size by reducing not only his expenses but also the lead time.

After the production was completed and the part passed the quality check, it was delivered at our client’s doorstep. Here you can see the final result after the part was mounted to the bike.

Fig. 3 Final product: part mounted to the bike